Describe the function of the Outbound feature in warehouse software.

- Sales Order Management

- Pick Item

- Pick List Bin Block

- Shipment Management

Warehouse Outbound

Warehouse management software (WMS) for outbound operations is a critical component of efficient supply chain management. It focuses on the processes involved in preparing and shipping goods from the warehouse to customers, distribution centers, or other destinations. Here's an explanation of outbound functionalities within WMS

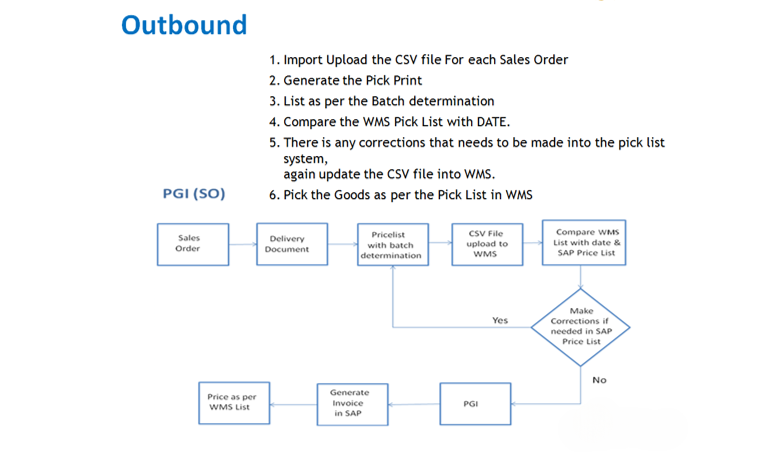

Order Processing

WMS automates order processing by consolidating orders from multiple channels and optimizing picking sequences to minimize warehouse travel time.

Pick and Pack Optimization

WMS optimizes picking and packing by creating efficient routes based on factors like order priority and item location, reducing time and effort for faster fulfillment.

Shipping Management

WMS integrates with carriers, automating shipping tasks like label generation and carrier selection, ensuring compliance and providing tracking for staff and customers.

Inventory Visibility

The software offers real-time visibility into inventory, allowing managers to track availability and allocate products accurately, minimizing stockouts or overstock.

Accuracy and Error Reduction

Automating processes with WMS reduces errors like incorrect shipments or mispicks, with barcode scanning ensuring accuracy at every stage of outbound operations.

Scalability and Integration

Modern WMS solutions are scalable and seamlessly integrate with ERP and CRM systems, ensuring consistent data across the organization's evolving needs.

Warehouse Inbound GRN (PO)

Warehouse management for inbound goods receipt notes (GRNs) for purchase orders (POs) involves several key steps to ensure that the incoming goods are properly accounted for and managed within the warehouse. Below are the main steps and considerations:

Enhance your warehouse operations with our high-speed warehouse management software.

Boost warehouse efficiency with our lightning-fast software. Streamline, optimize, elevate—start today!